US Disinfection Water

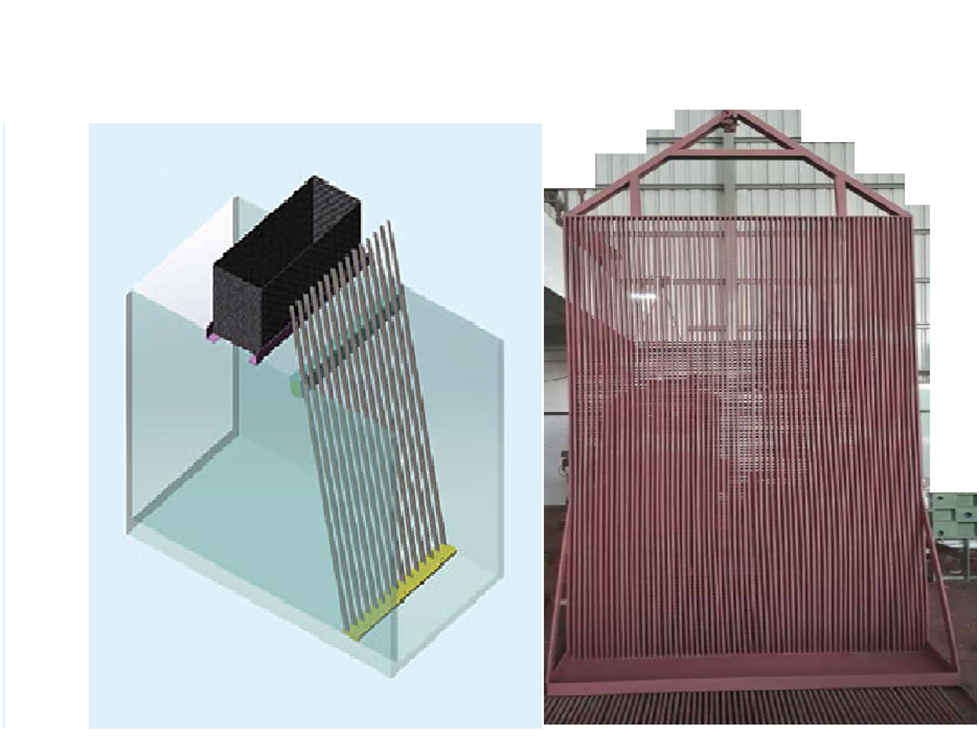

Bar Screen SLEW

Bar screen and screening water treatment is the first process unit operation used at wastewater treatment plants. Screening removes objects such as rags, paper, plastics and metals to prevent damage and clogging of downstream equipment and piping. Cleaning frequency depends on the characteristics of the wastewater entering a plant.

Bar Screen Operation and maintenance considerations

- Check and clean the bar screen at frequent intervals.

- Do not allow solids to overflow /escape from the screen bar screen

- Ensure no large gaps are formed due to the breakage of the screening water treatment.

- Replace breakage bar screen immediately.

- Mechanically cleaned screening system to remove larger materials because they reduce labor cost and they improve flow conditions and screening capture.

- Mechanically cleaned bar screen should have a standby screen to put in operation when the primary screening device is out of service.

Trouble Shooting of screening water treatment

| S NO. | PROBLEM | CAUSE |

|---|---|---|

| 1 | Large particles pass through and check the pumps | Poor operation /screen damaged |

| 2 | Up stream water levels is much higher than down stream level | Poor operation (inadequate cleaning) |

| 3 | Excessive collection of trash on screening water treatment | Poor operation |

| 4 | Excessive odor | Poor operation /trash disposal practices. |

Daily and weekly maintenance work

- Check gear box oil qty periodically and completely drain out oil and replace afresh as per manufacture’s recommendation.

- Check oil pump every day ,top up if necessary

- Check every day chain alignments and must periodically 4 hrs once chain cleaned or removed impurities materials.

Main use of screening water treatment

- To remove the suspended solids

- To avoided the pump cloaking

- To increase the Bacteria attachment in the FBBR system

- To reduce the Sludge Quantity in filter press

- To Reduce the short-circuit in Electro Coagulation System

- To avoided the solids cloaking in the air distribution system in Equalization tank

- To increase the air volume in Equalization tank

Project Brief of screening water treatment plant

Auto is engaged into printing of textile garments using pigments and reactive colours. The Effluent Treatment Plant is designed to treat 40m3 per day of the effluent to achieve the norms prescribed by the local governing bodies and BSR guidelines. The Factory presently produce only up to 10m3/Day Effluent. The ETP is designed for higher capacity considering the future expansion and addition of Washing Process.

Plan Capacity of screening water treatment plant

The Effluent screening water treatment Plant is designed to treat wastewater generated from the processing unit. The Effluent treatment plant is designed to treat 40m3/day of Washing & Printing combined effluent generated from the process house (Washing 15m3/Day & Printing 5m3/Day). The plant will be capable of operating at the flow rate of 2m3/hr. The Present Effluent generation is 10m3/Day and the Plant is operated for 10-12 Hours per Day with 50% flow rate.

Conclusion

The treatment plant is based on Electro-coagulation Treatment. Electrocoagulation system has distinct advantages for the treatment of Textiles industrial wastewater. EC Systems present high efficiency, easy operation and environmental compatibility this process involves generation of coagulants by electrolytic oxidation of a sacrificial anode (iron) by applying a direct current. The most widely used electrode materials in electrocoagulation process are iron. The hydrolyzed iron ions can form long chains of Fe-O-Fe-OH which may chemically adsorb a large amount of contaminants. Screening water treatment with bar screen is very essential for etp.