Sewage Treatment Plant

.jpg)

Sewage Treatment Plant

We Design, Manufacture, Supply, Erection and Commission Sewage Treatment Plant (STP) on Turnkey basis. Moving Bed Biofilm Reactor (MBBR) technology. Moving Bed Biofilm Reactor (MBBR) processes improve reliability, simplify operation, and require less space than traditional wastewater treatment systems.

Employs thousands of polyethylene biofilm carriers operating in mixed motion within an aerated wastewater treatment basin. Each individual bio carrier increases productivity through providing protected surface area to support the growth of heterotrophic and autotrophic bacteria within its cells. It is this high-density population of bacteria that achieves high-rate biodegradation within the system, while also offering process reliability and ease of operation.

This technology provides cost-effective treatment with minimal maintenance since MBBR processes self-maintain an optimum level of productive biofilm. Additionally, the biofilm attached to the mobile bio carriers within the system automatically responds to load fluctuations.

Process Benefits

Compact Design

A fraction of the size of conventional systems

Expandable

Capacity can be easily upgraded by simply increasing the fill fraction of biofilm carriers

Single Pass Process

No return activated sludge stream required

Load Responsive

Actively sloughed biofilm automatically responds to load fluctuations

Minimal Maintenance

No F/M ratios or MLSS levels to maintain

MBBR processes are an excellent solution for common wastewater applications including:

BOD Reduction

Nitrification

Total Nitrogen Removal

Moving Bed Biofilm Reactor systems deliver a flexible, cost-effective, and easy-to-operate means to address current wastewater requirements and the expandability to meet future loads or more stringent discharge requirements within a compact design

What Is Sewage Treatment?

Sewage can be defined as the polluting residue of the disposals from houses, offices, industry, factories as well as other kinds of public outlets. These disposals include waste and wastewater and the very process of eliminating contaminants from the disposals is referred to as sewage treatment. Sewage treatment plants take to physical, chemical & biological procedures for contaminant removal that ultimately leads to treated environmentally-safe wastewater. Sewage sludge is one of the most important by-products of sewage treatment which I a kind of semi-solid slurry. These treatment plants are a great aide in water recycling and the treated water can be used back for a number of tasks such as flushing toilets, harvesting or planting.

What Are The Types of Sewage Treatment Plants?

There are different types of sewage treatment plants operating today. These include-

- (MBBR) or Moving Bed Biofilm Reactor

- (SBR) or Sequencing Batch Reactor

- (MBR) or Membrane bio reactor

- (ACF) or Activated Carbon Filter

- (MGSF) or Multi-grade Sand Filter

- (SMF) or Suspended Media Filter

- Trickling filter

- Non-electric filter

How Does The Sewage Treatment plant work process?

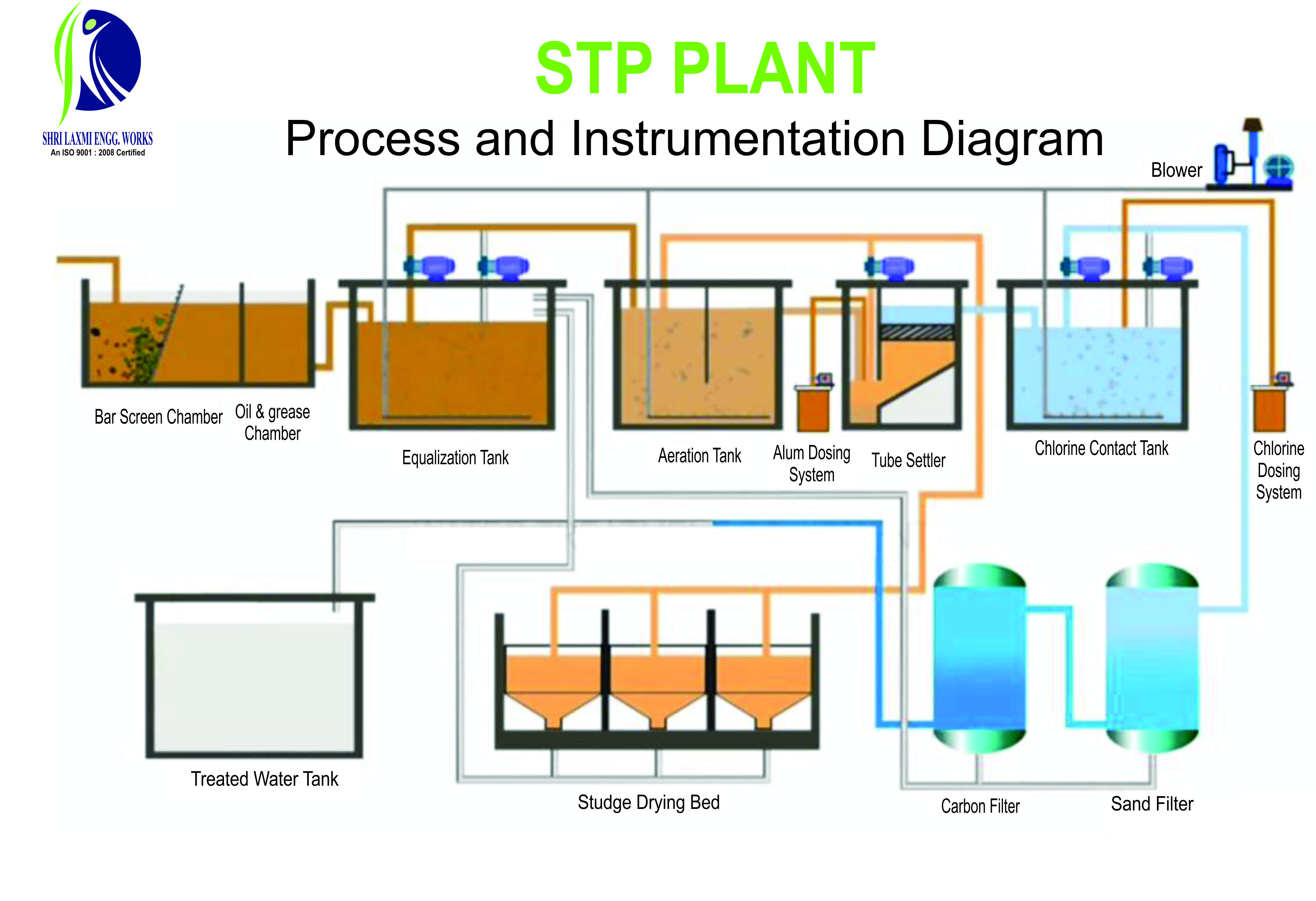

The Pre-treatment Phase

The entire treatment process starts with a pre-treatment phase. It’s the stage which works to remove materials conveniently collected from raw wastewater so that they can’t clog or damage skimmers or pumps of primary sewage treatment clarifiers. These materials could be leaves, tree limbs, trash etc. The sewage water gets thoroughly strained to sift out large objects that are carried through sewage stream. An automatic mechanical raked-bar screen is the most common aide here, especially for modern sewage treatment plants. However, smaller plants might go for manual screening. The solids collected are disposed in landfills or else are incinerated. The pre-treatment phase generally comprises of grit removal.

Primary Treatment phase

In case of primary treatment phase, the sewage is flown through big tanks or “primary sedimentation tanks” or “primary clarifiers”. These big tanks help sludge to settle down & make floating materials like oil & grease to rise up to the upper surface for an easy skimming. The fundamental mission of primary sedimentation phase is to generate a homogenous fluid that can be treated biologically as well as a sludge which could be separately processed or treated. The primary clarifiers are designed with mechanical scrapers that continuously drive the gathered sludge to a hopper located at tank base. It’s from the hopper, the sludge is pumped to advanced treatment stages.

Secondary Treatment Phase

This phase is dedicated to thoroughly degrade biological parts of sewage – the very biological contents derived from food waste, human waste, detergent and soap. It’s the aerobic biological procedure that goes to treat settled sewage fluid in STPs. The process could be performed in several ways and in all the methods, protozoa and bacteria consume the soluble organic biodegradable contaminants & bind a fair share of lesser soluble fractions to floe. The secondary treatment processes could be suspended-growth or fixed-film.

Tertiary Treatment

It’s the final stage that aims to further enhance the quality of treated wastewater before it’s ultimately released to receiving environ. Kelvin Water Technologies is one of the most renowned STP specialists in India. Our trained and seasoned wastewater treatment engineers are always here to help you with any assistance regarding servicing & maintenance of sewage treatment plants – and that too at highly reasonable costs.